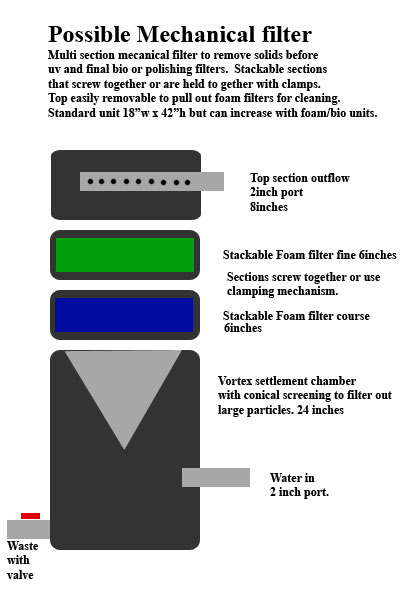

In seraching for a basic mechanical filter I keep seeing water garden filters that might work for a koi pond but their openings are too small or they are too small to handle the 3600GPH flow I am circulating. So I finally have put together a drawing of what I would like.

I want a multistage combo filter that can be adjusted as needed. Sections could be filled with media or left empty to add/reduce filtration as needed. My proposal is a pressurized pump fed multi-section 18″ diameter tube that has large port openings 2″ or larger and allows the owner to determine quality of filtration and frequency of cleaning by choice of media.

I want a multistage combo filter that can be adjusted as needed. Sections could be filled with media or left empty to add/reduce filtration as needed. My proposal is a pressurized pump fed multi-section 18″ diameter tube that has large port openings 2″ or larger and allows the owner to determine quality of filtration and frequency of cleaning by choice of media.

Water enters a bottom vortex settlement chamber with a conical screen to keep out large debris. Centrifugal forces would send heavier debris to the edges where it could fall to the bottom. Screen openings should be no more than 1/16 inch. The bottom section should have a pressure gauge port.

A second stage would screw on or be clamped on and contain a coarse foam filter media or perhaps bag of beads/media. A third stage containing finer foam media would be attached to act as fine particle capture. If desired, additional bio sections could be added for foam, mat, carbon, ammonia rocks, etc. Each stage would need a support screen for the media. And finally a top section which acts as the outflow chamber. The top section could also be fitted with pressure gauges, air ports, or possibly even a UV assembly. Openings between sections should be no less than 14 inches to allow maximum water movement even as filter layers get dirty.

Maintenance:

Daily/Frequent maintenance would require dumping the water from the bottom section to remove solids. This could be done while pump is on or off. Depending on fish load and other debris the foam sections would need weekly to monthly cleaning. IF foam sections are too fine cleaning will be more frequent. The conical screen should be easily removable for cleaning with a stiff nylon brush. Simplicity in disassembling and reassembling the system parts would be the key to making this maintenance friendly. Since the foam sections are intended as mechanical filtration rather than biological filtration, cleaning them with a hose would be OK.

Materials

The tube could be made of thick molded plastic, PVC, acrylic, or fiberglass. Stainless steel or aluminum could also be used but would increase the cost. Transparent sections would be really cool and let the owner see the dirt buildup. Material chosen would probably depend on how sections are joined. A base system would be sold with bottom section, 2 foam filter units, and the top section. Making it modular would allow owners to expand their system over time and refine their filtration. Additional add on items would be pressure gauge kits, aeration port kits, and replacement screens and media.

Hopefully there is a pond products engineer out there than can take my idea and make it work. The main challenge will be how to join the multiple sections without leakage. Perhaps some mechanism that works like a PVC Union does so each section has a threaded edge and an outer ring can screw down over the threads.

Other Possibilities:

The outer case does not have to be modular but merely has a removable top. There could be an insert into the main tube which is removable and configurable. Think of it like a strainer basket in a leaf trap, on a larger scale, and with layers. The design could possibly be reduced to 12″ diameter.

The other thing no one apparently has thought of is a large sock filter container, or perhaps it would clog too easily. Emperor Aquatics has one but it is only about 5″ in diameter and has 1.5″ openings. I want it bigger! 12″ diameter with 2″ports or larger with an easy to remove top and rinse-able/replaceable sock. This would be ideal once you have no algae and a relatively clean pond.I may try adding the sock to my Bio filter where water comes in.